Outline

Since expansion of business scale and the development of information needs, some chemical companies implemented the ERP system.

However, the following problems in the ERP system does not solve:

1. Variety, the documents are too cumbersome operation, the operator easily mistaken goods, or manually typing errors.

2. Inefficiency and mismanagement of materials, resulting in high costs.

3. Management rough, you can not know in time inventory.

4. Mixed wholesale goods mismanagement untraceable.

5. Inventory effort, disk are not allowed.

6. Different batches of the same product output aliquot unrecognized batch.

7. Buyers do not know the exact inventory, resulting in procuring materials can not meet the production or procurement of excessive wastage.

Newly formed companies use barcodes crownBarcodeandAutomatic Identification TechnologyandChemical industrySystem implementation experience for these companies to make the followingSolutionHelp solve chemical companies facing operational and management problems.

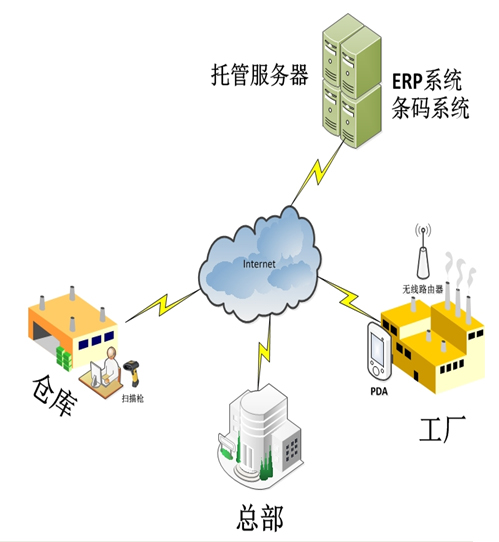

Program network diagram

Function module

System Management

【Operator management】:Operator to add, delete, modify,

【Rights Management】:Permission to the operator, can be refined to function module to add, delete, modify permissions.

Raw material storage

【Purchase Order Import】:Obtain purchase orders from the ERP system into the barcode

【Label printing materials】:According barcode rules, raw coding, batch print barcode labels, etc.

【Raw material storage Scan】:Use scanner, acquisition or PDA barcode scanning fast storage

【ERP Receipt generation】(ERP Interface):Receipt of raw materials to generate ERP

【Receipt Printing】:Single storage information printed materials

【Warehousing statistical reports】:A time period of raw storage statistics

Raw materials out of the library

【Picklist Import】:Get requisition from the ERP into the barcode system

【Raw materials out of the library scanning】:Use scanner, acquisition or PDA barcode scanning quickly out of the library

【ERP storehouse of raw materials to generate】(ERP Interface):Generation ERP storehouse

【Raw materials storehouse Print】:Print Delivery Information

【Raw materials out of the library statistical reports】:A time period of a library statistics

Product storage

【Production of single import】(ERP Interface):Imported from the ERP to obtain the production of single barcode system

【Production of a single print】:Print production order information

【Finished label printing】:According to rules of the finished bar, finished coding, batch printing finished labels and other information

【Product storage Scan】:Use scanner, acquisition or PDA barcode scanning fast storage

【Single-generation ERP product storage】(ERP Interface):Generate a single ERP product storage

【Finished Receipt Print】:Print a single information product storage

【Product storage statistics】:Certain period of time product storage statistics

The finished product

【Finished stocking single import】(ERP Interface):Obtain information from the ERP stocking single

【Finished scanning the library】:Use scanner, acquisition or PDA barcode scanning quickly out of the library

【Finished storehouse generation ERP】(ERP Interface):Generation ERP product storehouse

【Finished storehouse Print】:Printout Delivery Information

【Finished the library statistical reports】:Certain period of time the finished product statistics

Finished Returns

【Return label printing】:According returned products encoding and return label batch printing

【Finished return scan】:Use scanner, acquisition or PDA barcode scanning quickly out of the library

【Finished return a single generation ERP】(ERP Interface):Finished return a single generation ERP

【Finished return a single print】:Returns a single printout information

【Finished return statistical reports】:Finished return certain period of time statistics

For

【Raw materials / finished products for a single import】:Get requisition from the ERP system into the barcode

【Raw materials / finished products for scanning】:Use scanner, acquisition or PDA barcode scanning for fast

【ERP raw materials / finished products for a single generation】(ERP Interface):Generation ERP requisition

【Raw materials / finished products for a single print】:Print requisition information

【Raw materials / finished products for statistical reports】:Statistics for a certain time period

Inventory

【Inventory of single import】:Obtained from the ERP into a single bar code inventory system

【Inventory Scan】:Use scanner, acquisition or PDA barcode scanning quick inventory

【Overage shortage Report】:According to statistics carrying out data and in-kind product overage shortage

【Inventory of a single print】:Print a single inventory information

Other

【Mixed batch merge print】:After a mixed batch print a new label

【Mixed batch merge back】:Mixed batch of data query

【Split and print specifications】:Split into small size large size, and print out the small size of the label after split

【Feeding check】:Check whether the vote was wrong feed

【Valid management】:Products validity reminder

【Custom print labels】:Different customers can custom print labels

Related equipment

Printers and supplies:Raw materials and finished labels for printing

Scanner:Scan raw materials and finished products, fast operation

WirelessPDA:Wireless real-time scanning equipment, real-time scan data via WIFI returned back-end database.

Wireless Router:Provides PDA wirelessly connected network devices.

Fifth、 System Benefits

* Barcode recognition accuracy is high, reduce human error input.

* Improve inventory accuracy.

* Effective inventory space utilization and reduce operating costs.

* Effective inventory management and control, reduce the additional procurement, while ensuring that inventory to meet customer orders or production planning needs.

*Command and decision-making for the production sector to provide more valuable, more timely analysis of data. Making the management of enterprise storage onto a new level.

* Improve production speed and accuracy of statistics, summary statistics staff to reduce the difficulty.

* Clear division of labor departments, data connection used to strengthen the collaboration of various departments.

* Improve customer satisfaction, enhance the competitiveness of enterprises.

*Refined product inventory management, improve product inventory accuracy.