New to crown Barcode Warehouse Management System is the official introduction of the barcode warehouse management technology, warehouse receiving inspection, storage shelves, sorting out of the library, shift library shift, inventory and other operational aspects of the data for automated data collection, warehouse management to ensure operational aspects of the efficiency and accuracy of data input to ensure timely and accurate grasp of corporate real inventory data, reasonable to maintain and control inventory. Through the scientific coding, but also easily batch materials, shelf life management.

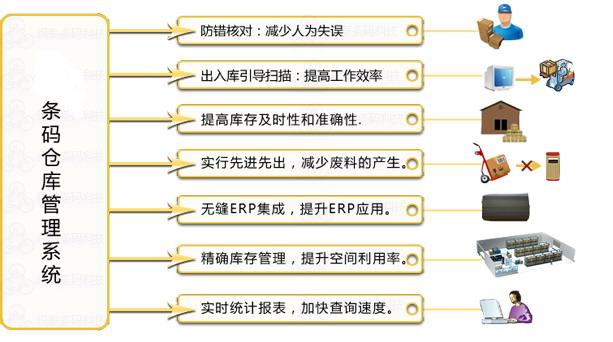

· Barcode Warehouse Management System: to solve the problem

- Low operating efficiency: by hand in the business of data entry office PC ERP system, can not move, not real-time, the operation is not convenient;

- Inventory is not accurate: after the tedious manual entry fallibility ERP documents, data latency, leading ERP inventory data is not accurate, and timely;

- Stay scrap heap: Items not good at a certain strategies (such as FIFO) under the frame, resulting in accumulation of spent waste, increasing inventory costs;

- Position items placed confusion: Although there has been divided positions, but not well at a certain strategy shelves (eg by category, orders), resulting in picking inefficient;

- Mistakes often occur out of storage: the storage of goods when relying on manual checking, quantity is easy mistakes, resulting in the wrong material, received the wrong goods, affect the production and quality of service;

- ERP plays a limited role: As the ERP system data is not accurate, timely, difficult to manage to provide a reliable basis for decision making;

- Production line positions shortage led to delays in production: the production site material consumption, workshop inventory and other information is not timely feedback to the member sends the material, resulting material is not timely made, affecting production

Barcode Warehouse Management System: After the implementation of revenue

Help Your Business:

New barcode warehouse management system into a crown full realization of the global inventory visualization through centralized management, master of all warehouse inventory, total inventory view from different angles, distribution, and plan in-transit, the actual in-transit inventory. Accurate inventory management, inventory turnover control of transfers between the various warehouses and provide the basis and support the shift library.

New to crown barcode warehouse management system in accordance with receiving, putaway, picking, shipping, shift, inventory and other bank of various operating modes will be broken down by the bar code mode operation records related workload, enabling employees task completion rates, cargo space utilization, timely delivery rates and inventory accuracy KPI assessment. System through the inventory log, a complete record of each system operation and inventory changes, when a cargo poor, it can be well documente.

New to crown barcode warehouse management system provides a powerful a library, storage, replenishment, inventory strategies; when the job instruction reaches barcode handheld terminals, the system according to pre-established strategy, implementation of the program automatically prompts staff; various types to meet customer shipping and receiving requirements (such as FIFO, LIFO, shipped in batches, etc.), based on the requirements to achieve paperless warehouse, saving forklifts and operating personnel workload for Job bottlenecks, optimize inventory placement layout.

New Barcode Warehouse Management System into a crown predetermined business processes, based on the documents through a unified format, different levels of permissions management, explicit different positions, different business operations requirements. Each department uses the same management system, running the same business process specification, so that every business has a well documented material, eliminate manual handling cases of irregularities arise, to ensure the implementation of standard processes.

New Barcode Warehouse Management System into a crown support routine statistical reports, including access to deposit daily report, material sales ranking reports, material color sales ranking reports, customer sales ranking reports, warehousing occupancy reporting. Flexible and convenient reporting tool to facilitate enterprises to develop their own reports required.

Computer Applications situation has become an important measure of corporate management level one of the signs. Greater emphasis on the development of modern enterprise application management computer, so the use of standardized, systematic, standardized management, bar code management, unified identity of foreign goods is to enhance the corporate image and competitiveness of the favorable insurance

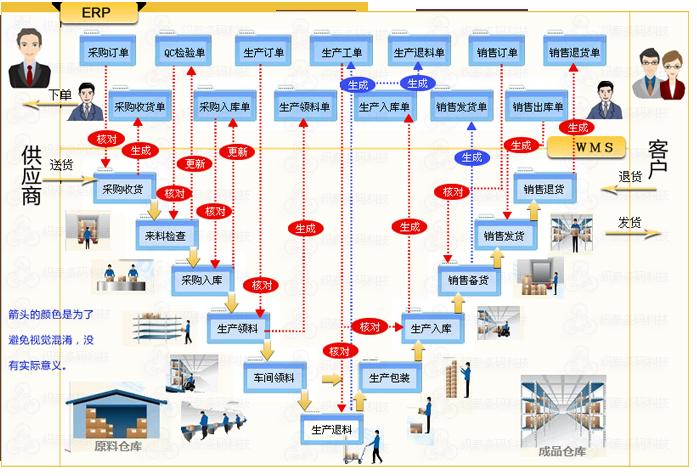

Barcode Warehouse Management System: business process diagrams

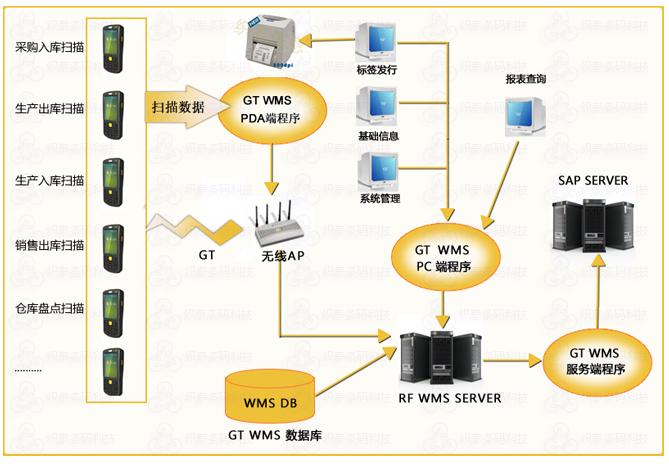

Barcode Warehouse Management System: System Architecture

Solutions

(1) Production planning and procurement plans

Production department to develop production plans based on sales orders, purchasing department in accordance with production planning and inventory produce procurement plan, and issued to the supplier.

(2) Supplier label

We recommend suppliers in their product packaging paste barcode labels, labeling categories, batch number.

There are several ways to produce:

A. Suppliers barcode printer to print out, paste;

B.Procurement plan issued, the print label together with the purchase order sent to parts suppliers (may require suppliers to purchase).

(3)Receipt of raw materials

Materials served as already provided for barcode labels, warehouse staff that receipt; if no barcode labels, according to the shipping product, print the appropriate bar code labels.

(4)Raw material storage, shelves

Scanning on the shelves barcodes, material box upper barcode, the job is completed after the upload system, generate material storage documents.

(5)Picklist

Before the start of production operations, according to the production plan planners determine the finished batch number, lot number and product entry in the system as a unit producing a single feeding, picking operation people scan bar code on the box and the corresponding positions stacked bar code in the system after the job is completed importing data collection, generating picklist. In the system for the documents for review.

(6)Semi Jincang

Semi-manufactured finished, semi-finished bar code label affixed, warehouse manager scans the bar code on the box and the corresponding stacking positions barcode job is finished collecting data in the system to import, produce semi-finished products into the warehouse.

(7)Semi-finished products out of the warehouse

Production operations before the start of program staff according to the production plan identifies product lot number, and product lot number for the units in the system entered production feeding single, picking operation people scan semi crates bar code and the corresponding stacking positions barcode, job after the completion of the system importing data collection, generating production semi requisition.

(8)Finished Jincang

After finished products, finished products affix barcode labels, warehouse manager scans the bar code on the box and the corresponding positions stacked bar code in the system after the job is finished importing data collection, produce finished products into the warehouse.

(9)Finished products out of the warehouse

Enter the sales order number, the system lists the single out of the products in the warehouse storage positions (warehouse keeper can be printed out, press inventory pick), the sales of single download to data collection, to find to ship products scanning positions barcode on the product packing box barcode job is done in the system to import collected data to produce the finished product warehouse.

(10)Data query and reporting

The data for this system for data analysis, generating various related reports, such as: inventory reports, Product age reports, returns, tables, tables and other inventory differences. The relevant statistical data, query, and analysis. System can be based on product barcodes, models, time, plan number, warehouse, between units keyword search product delivery, receipt, issue the receive direction and location tracking information, providing a storage volume, the number in the library, picking quantity, etc. statistical information to facilitate financial and suppliers settlement money. Can be traced through the product material suppliers.

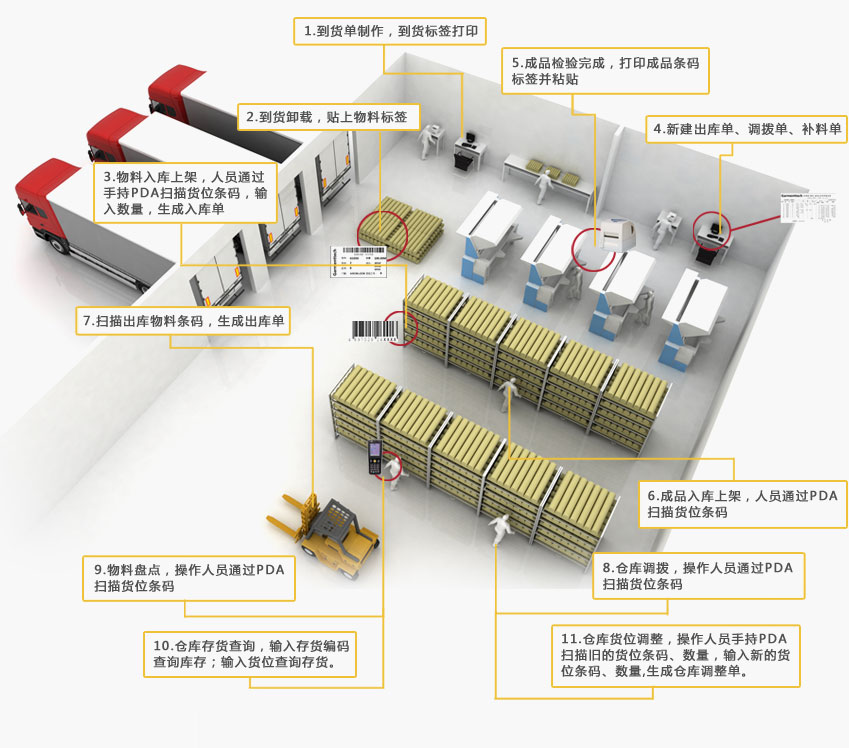

(11)Data collection procedures

Barcode data collection can be prepared in accordance with the rules, scan the bar code information, and display name, type, batch number, warehouse location and other information to facilitate raw materials, semi finished goods receiving, picking, inventory, shipping and so on.

(12)Inventory

Job, select the inventory of materials (raw materials or finished products such as information, generate inventory receipts, inventory single worker will download data acquisition, the scanned bar code on the package of materials and cargo space, data collection, the job is completed, the data collected into the system, the system will import inventory data collection system after the original inventory report be checked, adjusted vouchers and adjust the report to generate.

System features:

1.Using wireless PDA barcode data collection jobs, all jobs from the computer mouse barcodes directly on-site storage, a library, inventory, allocation, replenishment and other warehouse operations retreat.

2.Real-time interactive data warehouse operations, to ensure real-time data updates

3.In the field of data warehouse queries, check

4.More comprehensive than the simultaneous operation of multiple services

5.Business data (cargo space, warehouses and other data) error correction

6.Customers, purchasing, sales, product sales and other types of management decisions ranking report query functions

7.Background business processing, check the function