H2000 Enhanced mixed base

Premium Wax/Resin Thermal Transfer Ribbons

Outstanding performance

H2000 give different materials mixed base ribbon labels provide excellent print quality, in addition to ordinary things, including rough coated paper, uncoated paper, tag and membranes. Also provides good anti-scratch, stain or solvent properties, print clearly.

Application:

- Horticultural and nursery

-Timber

-Outdoor

- Medicine and Health Care

- Car

- Shelves and boxes of labels

- Asset tracking

- Distribution route management

- WIP (Machining program) tag and label

- Retail packaging labels

Recommended media

-Tag and label, with or without coating can be

-Coated Paper

- Synthetic Paper

- Film category(PET,PVC)

-Tag

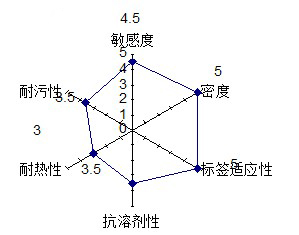

Star chart

The figure represents the H2000 printed on coated paper tag and label special applications. Performance rating based on mixed base ribbon controls. Level 1 to Level 5,5 best.

Technical Note

Film thickness: 4.5Micron

Total ribbon thickness <9.0Micron

Send density: >1.7 MacBeth Scale

Toner dissolution temperature: 80º C

Storage Conditions

To ensure optimal performance, the following conditions of use, transport and storage:

- The ribbon at 5 º C (41 º F) to 35 º C (95 º F) and 45% to 85% humidity optimum printing results

- Recommended transport conditions 5 º C (41 º F) to 45 º C (113 º F) temperature, between 20% to 85% relative humidity between

- In order to ensure the performance of the ribbon, the proposed storage period is less than one year and storage temperature -5 º C (23 º F) to 40 º C (104 º F), humidity 20% to 85%

Please note: thermal transfer ribbon should avoid direct sunlight and exposure to humid environment, otherwise it will damage the ribbon