B112 Enhanced edge pressure mixed base

Near Edge Premium Wax/Resin Thermal Transfer Ribbons

Outstanding performance

B112 Printed ribbon give mixed base end side print print head using different materials labels provide excellent print quality, suitable for high-speed printing, there is a wide range of label adaptability, excellent scratch resistance and sensitivity.

Application:

- Horticultural and nursery

-Timber

-Outdoor

- Medicine and Health Care

- Car

- Shelves and boxes of labels

- Asset tracking

- Distribution route management

- WIP (Machining program) tag and label

- Retail packaging labels

Recommended media

- Ordinary uncoated paper

- Coated paper and tag

- Synthetic Paper

- Polyethylene film

- Polypropylene film

- Mylar

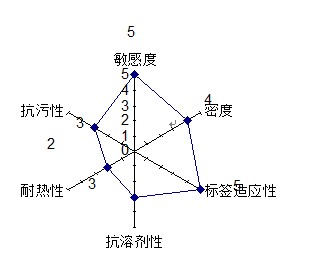

Star chart

The figure represents the B112 printed on coated paper tag and label special applications. Performance rating based on mixed base ribbon controls. Level 1 to Level 5,5 best.

Technical Note

Total ribbon thickness <8.0Micron

Send density: >8.0

Toner dissolution temperature: 70º C

Storage Conditions

To ensure optimal performance, the following conditions of use, transport and storage:

- The ribbon at 5 º C (41 º F) to 35 º C (95 º F) and 45% to 85% humidity optimum printing results

- Recommended transport conditions 5 º C (41 º F) to 45 º C (113 º F) temperature, between 20% to 85% relative humidity between

- In order to ensure the performance of the ribbon, the proposed storage period is less than one year and storage temperature -5 º C (23 º F) to 40 º C (104 º F), humidity 20% to 85%

Please note: thermal transfer ribbon should avoid direct sunlight and exposure to humid environment, otherwise it will damage the ribbon