Bar code quality tracing system: to solve the problem

· Incorrect use of the material: artificial materials used in production line error, can not be timely discovery;

· Material Tracking: If a certain part of the material was destroyed, not a clear understanding of the material toward;

· Production drain station: manual production line, if the product will produce some missing links, is not timely remedied;

· Real-time data: artificial production of all data records, errors and circumstances frequently do not occur in a timely manner.

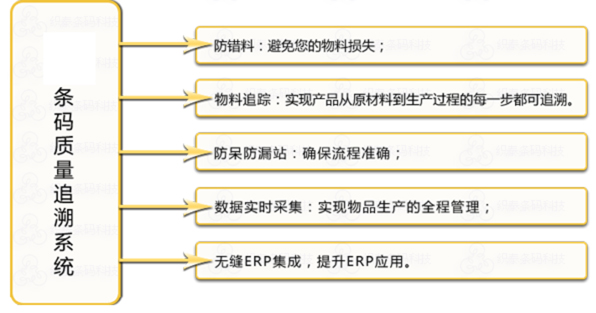

Bar code quality tracing system: After the implementation of revenue

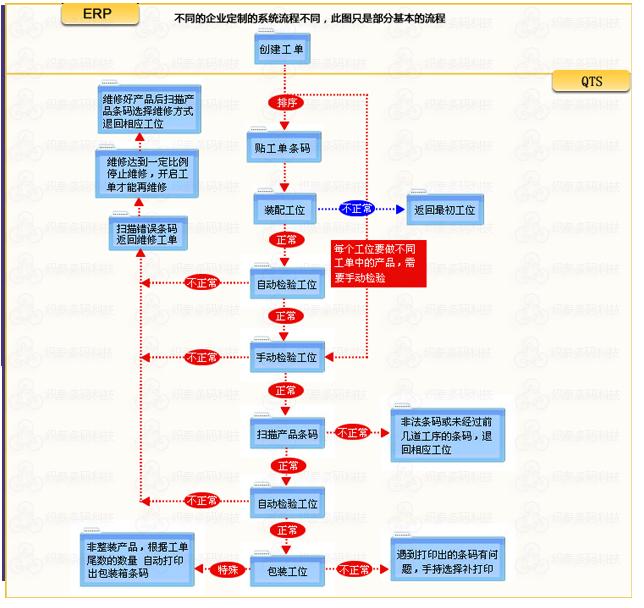

Bar code quality tracing system: business process diagrams

Bar code quality tracing system: the main function modules

Proofing material

Implementation of this system to the raw materials, production processes of the station setting, every step of the testing error prevention function, can be timely reminder and testing materials are produced error messages, timely corrections and reduce losses.

Raw material traceability

Raw materials for survival against all the information can be based on the relevant barcode searching and retrieving such material waste and confusion can be solved in time. And can achieve the production process from raw materials to products

Each step can be traced, the process can be traced to the human, machine, material, method, ring, measuring and other information;

Foolproof leakproof station

The system for the production of each session are set detection function, if the production of the raw material has not been a particular station, the alarm system will give prompt and timely manner, never let the material proceed to the next

A station.

Real-time data

Automatic test equipment Data acquisition, combined with barcode scanner / RFID electronic tags, realize the whole process of quality management;

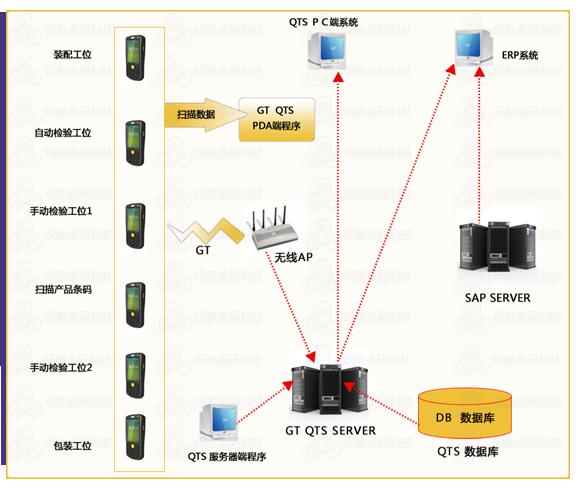

Bar code quality tracing system: System Architecture